Market

RARE WHISKY 101

RARE WHISKY 101

Andy to David – “What would happen if we drew inspiration from the craft brewers and made spirits?”

David – “No, idea, let’s find out!”

Research – we both love Glenmorangie Signet (good research!) – a weird, flavoursome single malt, an alcohol infused tiramisu with espresso coffee notes….wow. Spoke to Dr Bill and we hatched a plan.

Met Simpsons malt and chewed an amazing range of “speciality malts” and could not believe the range of flavours and textures, so we set out to further understand the impact of speciality malt flavour on new make spirit.

The Controls – 100% Golden Promise, 4 yeasts – 2 brewers and 2 cultured.

The Wood – 12 amazing sherry butts from Tevasa Cooperage – the same supplier I used at Macallan back in the 1990s.

The Questions – where should we do this?

One obvious answer – with our mates at the Glasgow Distillery Company (GDC).

Glasgow Distillery – The perfect playground for grownups.

It boasts a perfectly formed small lauter tun, 4 easy to keep clean stainless steel fermenters and 2 magical copper pot stills. A way to keep each and every mash separate from the next using a range of transit tanks, allowing us to collect low wines, foreshots, spirit and feints from every single mash and fill 1 cask from 1 mash. Perfect control, perfectly discreet, perfectly simple.

But most importantly, a team of talented, helpful and innovative people – Liam, Dr Jack, Lok and Freddy.

The plan was hatched!

David, Andy and Dr Jack

The Recipes – what mix should we use? Can we go 100% speciality malt? Will it mash okay? Will it ferment? Will it distil? Will it yield any alcohol?

Back to first principles – we worked with Tim McCreath at Simpsons Malt and did some lab scale analysis of various speciality malts recipes.

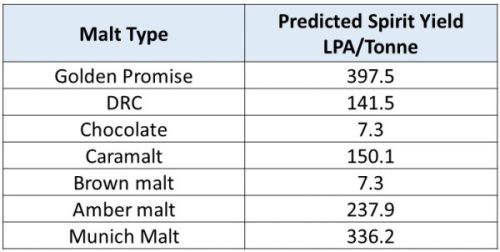

Lab PSY (predicted spirit yields) ranged from 7.3 litres of pure alcohol per tonne to 397.5. Wow, what a massive spread!

Distillers today typically return a yield of 410-425 litres of alcohol per tonne….but are they creating flavour?

Costs – of course this needs to be factored in. The speciality malts are much more expensive that traditional distilling malts. Plus, we were buying in tiny batches. More cost!

Writing up every aspect of recipe and distillation could take forever, so we will share information in general terms. We bought crushed (already milled) malt from Simpsons and we paid anywhere from £600 to £750 per tonne. Imagine paying £750 per tonne to yield 7 litres of alcohol! A pretty expensive exercise….

How about recipe planning? Again we sought a collaborative approach and organised a planning session (in the pub) with the Glasgow distillers and we each picked a recipe we felt would or could work to deliver relatively easy processing, reasonable yields and maximum flavour.

A fun night drinking beer and chewing on all kinds of wonderful malt

The plan was hatched and agreed and we asked Simpsons to confirm the PSY by conducting lab scale mashing and analysis.

So, we had a plan and an indication of likely yields – ranging from a low of around 296 l/t to 397 l/t – a huge range in yield and hopefully a huge range in flavour impact. Would inclusion of speciality malts deliver the flavour impact we craved? Or would the fermenting and distilling process strip out and lose all the character we sought?

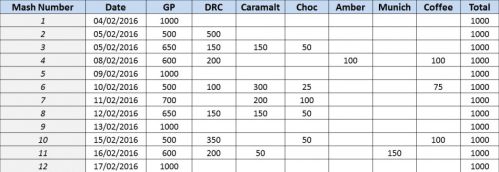

Malt recipes – proportion of specialist malt

Processing – we agreed to follow the classic 3 water mash.

Strike 68C to get 64C at the spout to activate enzymes and convert starches/large sugars to fermentable sugars.

Rest briefly, balance to underback, vorlauf (or recycle weak worts) and then pump to FVs and cool worts to 20C.

Add our 4 yeasts – 2 dried culture yeasts (AB Mauri Pinnacle and SAFWhiskyM1) and two fresh brewers yeasts (A top fermenter and a bottom fermenter) with the aim of creating true complexity!

And start the fermentation ASAP.

Sparge on the second water, drain, cool and collect in FV, sparge on the third water and collect in heating tank for next mash (although we didn’t do that for every mash!).

Our Original Gravities (Ogs) ranged from 1047 to 1055 – low by many of today’s standards.

We fermented to achieve maximum conversion of sugars to alcohol and this ranged from 70 to 112 hours before sending to the wash still.

Our final gravities were hugely variable and a correlation (as expected) was found between mashes with no or low levels of speciality malts fermenting well versus high speciality malt inclusions fermenting less well.

Alcohol strengths at many large and efficient malt distilleries today can range from 8 to over 10%. Our trials yielded a range of 5 to 8%! Poor for yield efficiency, but hopefully great for flavour!

A flying Scotsman for breakfast

We typically collected some 5,000 litres of worts per fermentation, fermented for around 4 days and then split the FV in half to give 2 wash still charges.

So, across the course of our 24 wash distillations our initial running strengths varied from the mid 40%s to the mid-60%s.

Our low wines average strengths ranged from 15.7% to 22% – again a huge range, which correlates perfectly with the mashing recipes we have used. Most distillers today would have very consistent low wines abvs between 22 and 26%. After all, they are looking for consistency of production and are aiming to make the same low wines and same spirit day in day out. They are new-make factories. We are not. We celebrate diversity in the pursuit of a range of flavours.

By using Glasgow Distillery Company we were able to keep each run discreet and store them in 1T transit tanks. This allowed us to control, manage and monitor each and every mash, and finally fill all the new make spirit (NMS) in a single butt from a single mash.

Each run (1/2 a mash) typically gave us around 130 Litres of Alcohol (LOA) to 180 LOA per run. Our flow rates were deliberately very slow and ranged from 1.2 litre per min to 3.2 l/min! This was collected and used to charge the spirit still.

As this was a discreet experiment, we did not want any recycled liquids from any previous GDC runs. This meant we needed to ‘build up’ our foreshots and feints until we had a better ‘balanced’ system where our spirit still charges could become more consistent.

We needed to collect and build up our low wines, foreshots and feints to give enough charge liquid for our spirit still processing. This is where it all started to get critical. Could we recover the flavour created from our speciality malts? Distillation is, by its very nature, a simple process to purify the feed stock material. Collect what you want and throw away what you don’t. After much time at Diageo and The Macallan I am a fan of small stills and slow distillation and a very narrow spirit cut to concentrate the fruity, estery notes – but would this work for rich, chocolate malty flavours?

Steam on!

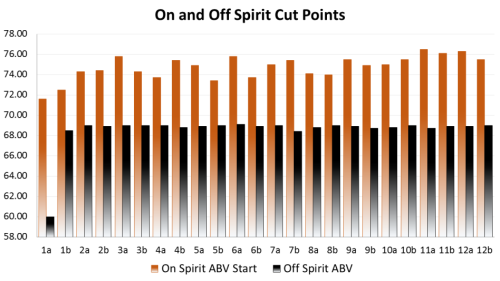

So, the detail of our spirit distillations – when we went on to spirit and then off spirit to collect the ‘heart of the run’. This clearly shows the feints build up in our first 2 mashes and 4 spirit runs – 1a, 1b, 2a, 2b – until, we reached a ‘steady and balanced’ state. The variation in ‘on spirit”’ from mashes 3 to 12 show the impact higher or weaker washes from fermentation can have.

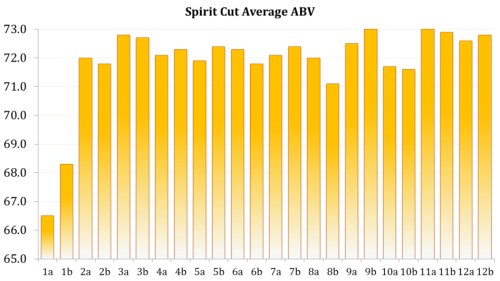

Focusing now on the average spirit strength we can again see the feints build up required until we got a more steady state and consistent spirit cut average around 72% abv +/- 1%.

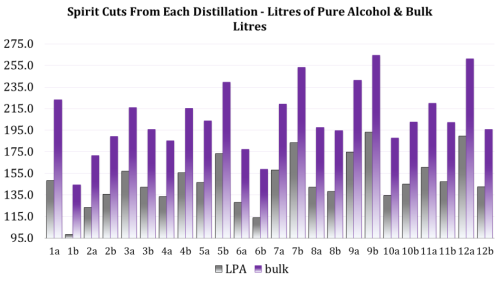

To illustrate the point more fully we have looked at the quantity of both the ‘litres of pure alcohol – or LPA’ – and the ‘bulk spirit’ created from each of the 24 spirit distillations.

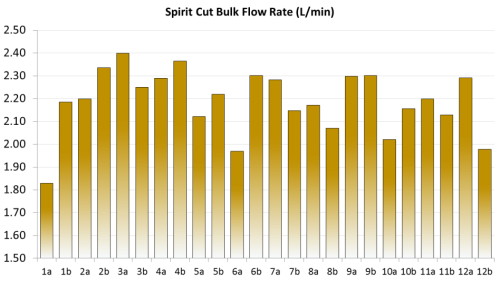

And finally, the rate of distillation. As discussed previously we wanted a very slow, even, gentle boil to ensure good reflux and a balanced recovery of the purest and most flavoursome characters from these experimental batches. We believe this to be the slowest spirit cut in the Scotch whisky industry.

And so to wood. What wood? Well, given my experience and the richness of our expected new make spirit we opted for first fill Spanish oak ex Sherry butts from Tevasa cooperage, seasoned with wines from Gonzalez Byass in Jerez de la Frontera.

A full load of over 50 mighty 500 litres butts were sourced, delivered to Glasgow and nosed, with RW101 picking 12 for our bespoke distilling project.

We were looking for select casks that offered up aromas of rich dried fruits, spicy tannins (clove, cinnamon, nutmeg, ginger), orange zest and toffee sweetness.

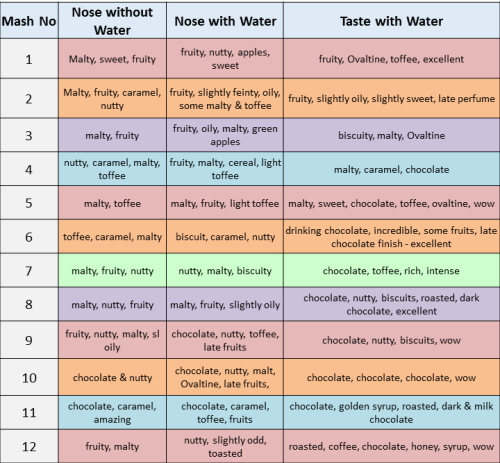

But back to the spirit, the essence of what we were after. What was it like?

Clearly we have recovered a range of amazing characters in our spirit. We have the classic fruity notes as would be expected from 100% distilling malt – fruits, apples, pears, maltiness and nutty.

But even more exciting we have captured notes of chocolate, biscuity, toffee, nutty, golden syrup, roasted coffee, honey.

So, what happens next? We wait….and wait. And draw samples every 6 months to assess progress. Will we lose the speciality malt characters we have worked so hard to preserve? Will the wood dominate and hide those flavours? Will there be a symbiotic relationship and the wood and chocolatey notes support and enhance each other? Will things change to create new flavours? Will we lose fruit and gain spice? Will we create the world’s first ‘chocolate orange’ single malt? Only time will tell! We will report back soon…..

Cheers,

David & Andy

We’ll respect your privacy. Also, you can unsubscribe at any time.

We’ll respect your privacy and you can unsubscribe at any time.